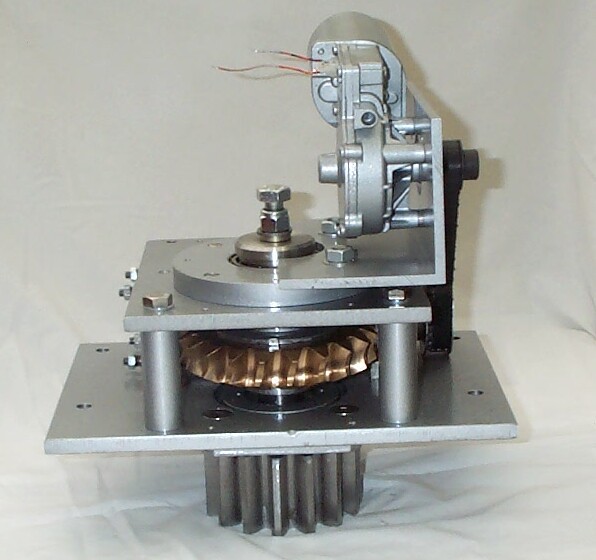

The slewing ring from a small crane or digger (diameter 600mm) will form the main Azimuth bearing of the new mount.The pinion that will drive it is to the right. Inside are the Worm and wheel which will drive the pinion from a small 24V DC electric motor.

The Waveguide 16 bend is for scale.

The next stage is to remove the dish so that the existing mount can be removed.

The "Pan" mechanism from the existing mount will be modified to provide the Elevation drive for the new mount.

|

|

| A timber frame was constructed | so the dish could be lifted off using a Fork Truck |

|

|

| The Base with azimuth bearing being fabricated | Test assembly |

|

|

| The metal structure arrives at G4NNS | The Azimuth and Elevation mount begins to take shape |

|

|

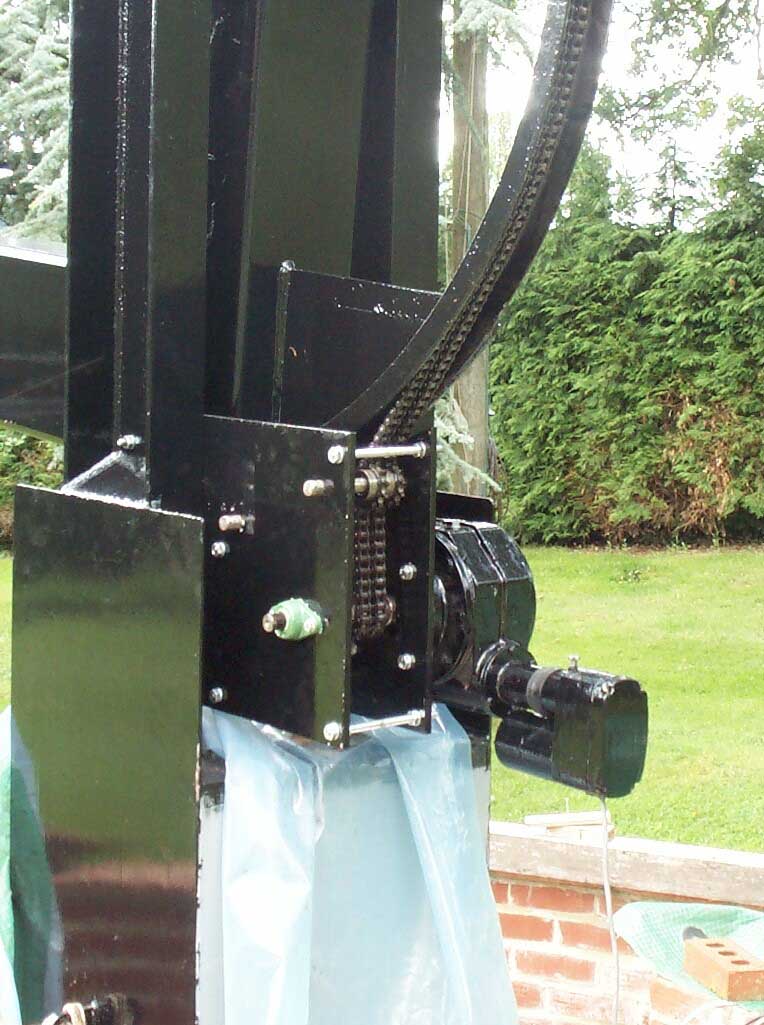

| The cables in flexible conduit lie coiled in the "cable well" to allow for about 400 degrees of rotation | The Elevation drive uses chains around an arc |

|

|

| The azimuth drive - precision engineering by Ian G8CPJ | A 24V DC motor drives a pinion via a "worm and wheel" The pinion drives against the static gear on the slewing ring |

|

|

| The dish being replaced using a farm loader | The support frame is removed and the dish is free again! |

|

|

| Even the control gear looks ready | but there's still a lot of wiring to do ! |

|

|

| The wiring is done and the Azimuth encoder is in place | The installation is almost complete and ready for calibration |

|

|

| A laser is attached to the dish to assist with calibration and measurement of backlash in the drives and encoders | A window some 25m from the antenna is used as a reference point. See red laser dot on the bottom ledge. |

|

After calibration the skyline was scanned to plot the obstructions (which are mainly trees) so that I could establish the extent of my unobstructed “window”. This was done by reducing elevation at various intervals of azimuth until the noise level rose by 1dB due to ground noise.

Updated Aug 2018

Return to the Radio Astronomy page

Return to the G4NNS Home page

Visit the Hydrogen Line Observing Group web pages